Interoperable of NextGen Industrial Plant Design suite

AutoPIPE Vessel CONNECT Edition

Pressure Vessel Design software

AutoPIPE Vessel

![]()

AutoPIPE Vessel ที่ขับเคลื่อนโดย Microprotol ช่วยให้ขั้นตอนการทำงานอัตโนมัติเต็มรูปแบบ รวมถึง global codes ที่สมบูรณ์และการใช้งานสำหรับ pressure vessels heat exchangers, tanks และ air coolers เพื่อมอบประสิทธิภาพการผลิตที่มากขึ้น การออกแบบที่ปลอดภัยยิ่งขึ้น การผลิตที่คุ้มค่า และปรับปรุงการทำงานร่วมกันในโครงการ AutoPIPE Vessel ออกแบบ Vessel ให้เหมาะสมที่สุดอย่างแท้จริงภายในไม่กี่นาที

เพิ่มผลผลิตและการออกแบบที่แม่นยำสำหรับการทำงานที่ปลอดภัยของ vessel ภายใต้สภาวะการโหลดทั้งหมดสำหรับ pressure vessels, heat exchangers, tanks และ air coolers บรรลุการปฏิบัติตามมาตรฐานระดับภูมิภาคและระดับโลก รวมถึงโค้ดการออกแบบ pressure vessel ในช่วง 10 ปีที่ผ่าน regional wind, seismic, wave, และ blast-loading codes ปรับปรุงความยืดหยุ่นในการจัดอันดับใหม่และปรับปรุง vessels ที่มีอยู่ คุณสามารถออกแบบสำหรับทั้งโครงการใน brownfield และ greenfield และลดเวลาการออกแบบและการทำงานซ้ำโดยกำจัดการคาดเดา สร้างความมั่นใจใน vessel design และปรับปรุงความสามารถในการแข่งขันของคุณด้วยคุณภาพการออกแบบที่สูงขึ้น

Capabilities

- ปฏิบัติตามโค้ดและมาตรฐานอุตสาหกรรม

- ออกแบบและจำลอง pressure vessels

- การสร้าง vessel detail drawings

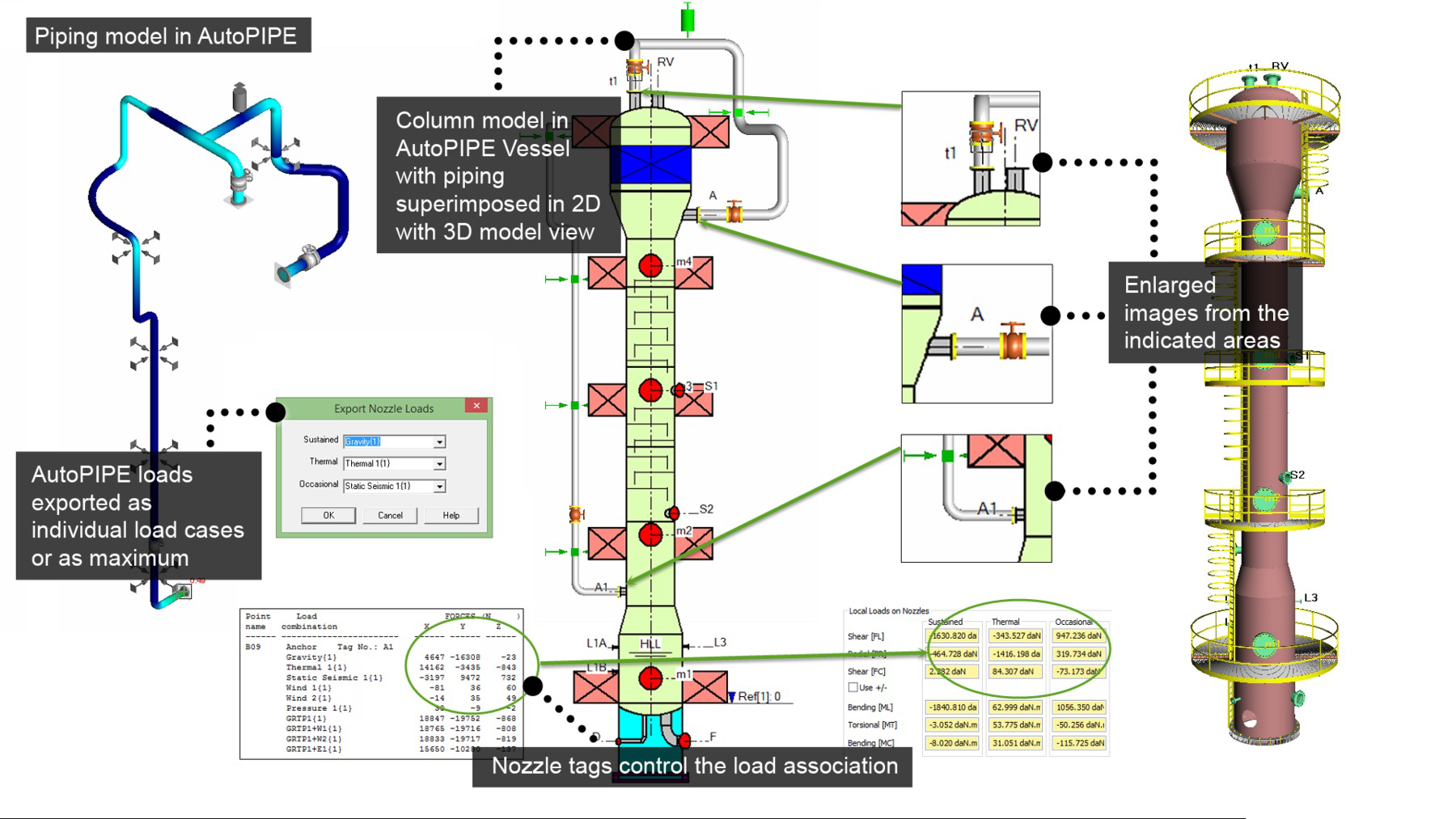

- อ้างอิงโมเดล piping สำหรับการวิเคราะห์ vessel

ปฏิบัติตามโค้ดและมาตรฐานอุตสาหกรรม

ตรวจสอบให้แน่ใจว่าโครงการของคุณสอดคล้องกับมาตรฐานการออกแบบระดับโลกมากกว่า 30 มาตรฐานในอุตสาหกรรมพลังงาน, นิวเคลียร์, offshore, chemical, และ oil and gas รวมแนวทางและขีดจำกัดการออกแบบของ ASME, British, European, French, Japanese, Russian, API, NEMA, ANSI, ASCE, AISC, UBC, ISO และ WRC

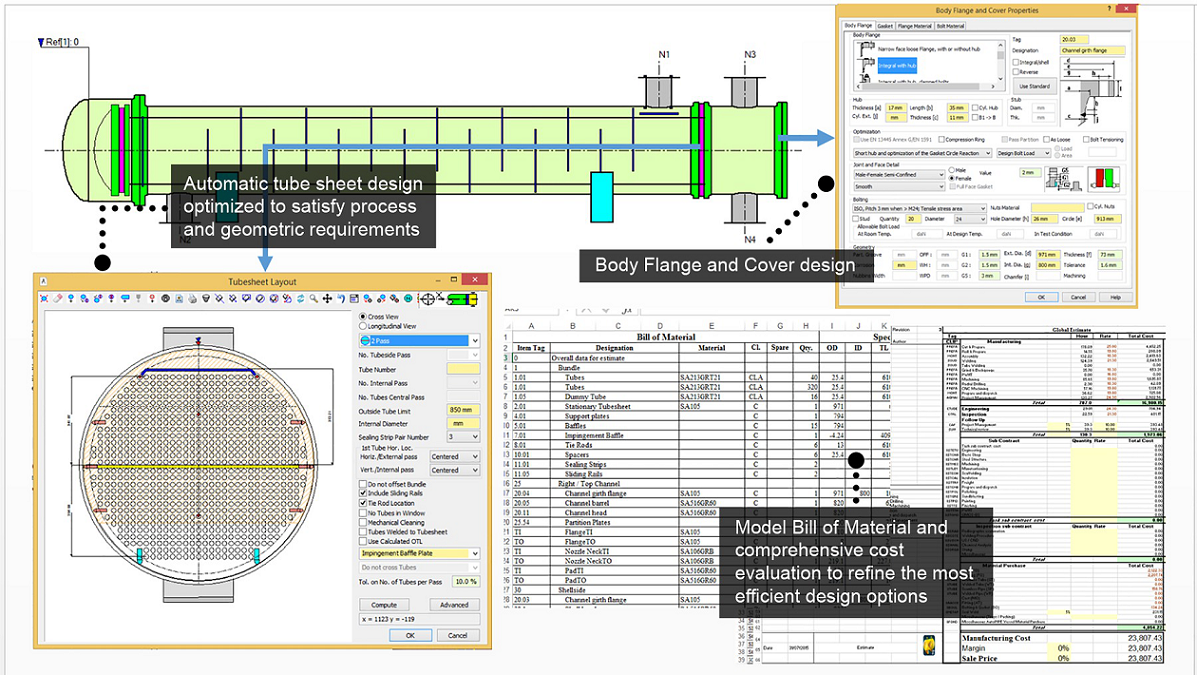

ออกแบบและจำลอง pressure vessels

ออกแบบและสร้างแบบจำลอง pressure vessels อย่างรวดเร็วตาม international design codes และวิธีการ local load เพิ่มประสิทธิภาพการออกแบบหน้าแปลนของคุณเพื่อลดต้นทุนตามรหัสการออกแบบ เพื่อให้มั่นใจในการออกแบบ vessel ที่ปลอดภัย สร้างรายการวัสดุ, รายละเอียด vessel drawings และ รายละเอียด parametric 3D solid

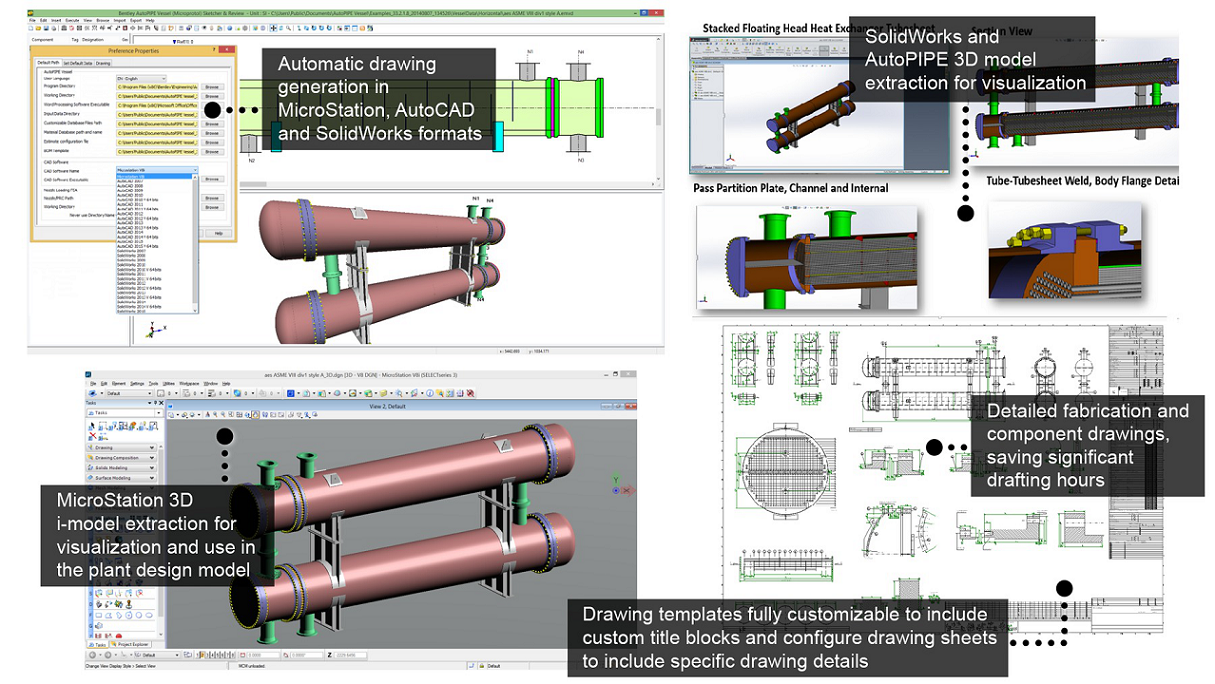

การสร้าง vessel detail drawings

ลดเวลา manual drawing และการทำงานซ้ำด้วย detailed drawings แบบอัตโนมัติ สร้างแบบวิศวกรรมที่มี dimensioned, จัดการพื้นที่สีขาว และกำหนดค่า drawing sheet layout ปรับแต่งข้อมูลและรายละเอียดการเชื่อมต่อให้ตรงตามมาตรฐานของผู้ผลิต

อ้างอิงโมเดล piping สำหรับการวิเคราะห์ vessel

ประหยัดเวลาและลดความผิดพลาดโดยการนำเข้า nozzle loads จาก AutoPIPE ไปยัง AutoPIPE Vessel เพื่อการวิเคราะห์บน vessel shell